Table of Contents

- Reading Time | 8mins

Introduction

Welcome to Your Ultimate Cantilever Racking Repairs Guide!

Cantilever racks are essential for efficient and organised storage systems, especially for storing long, bulky items like lumber, pipes, and sheet metal. However, like all storage solutions, cantilever racks require regular maintenance and occasional repairs to ensure their safety and functionality.

This guide will help you identify common issues, provide troubleshooting tips, offer step-by-step DIY repair instructions, and advise when to call in professionals.

By following this guide, you’ll be able to maintain your cantilever racks effectively, ensuring they remain a reliable part of your storage system.

Common Issues with Cantilever Racks

Warping or Bending

- Causes: Overloading, incorrect installation, wear and tear.

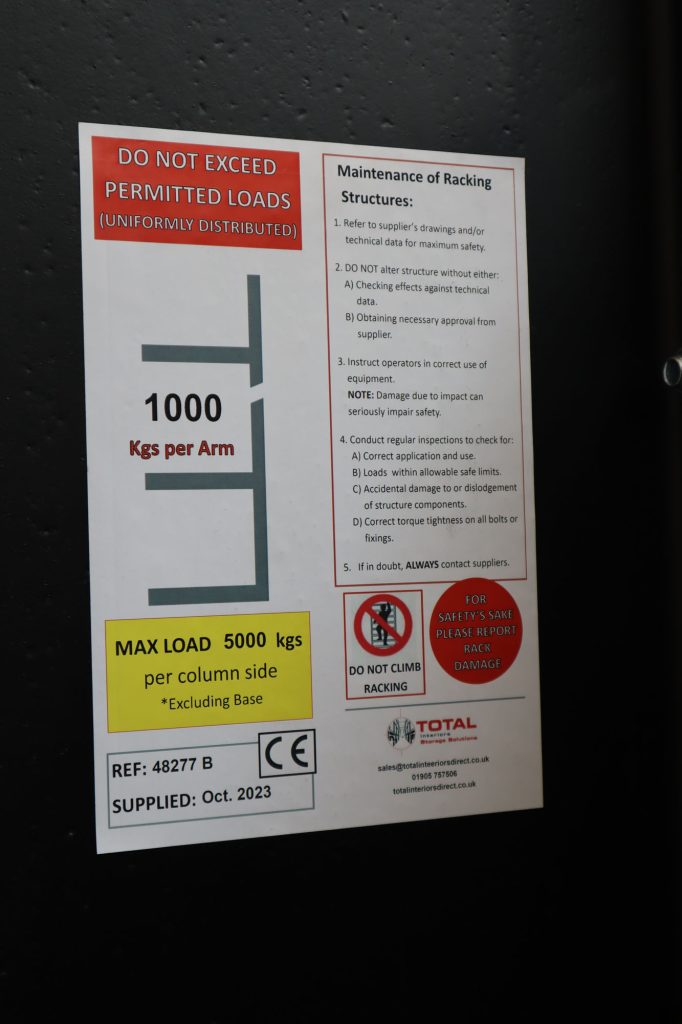

- Inspection Tips: Regularly check for any signs of bending in the arms or columns. Ensure that the weight distribution is even and that the loads do not exceed the manufacturer’s specifications.

Loose Bolts and Connections

- Causes: Vibration from daily use, insufficient tightening during installation.

- Inspection Tips: Regularly check and tighten bolts and connections. Look for any parts that might be coming loose due to regular use or improper installation.

Corrosion and Rust

- Causes: Humidity, poor-quality materials, lack of maintenance.

- Inspection Tips: Inspect for signs of rust on the metal surfaces. Pay special attention to areas prone to moisture or chemical exposure.

Damage from Impact

- Causes: Forklift collisions, improper handling.

- Inspection Tips: Look for dents, scratches, and other signs of impact damage. Ensure that these are addressed promptly to prevent further structural issues.

Troubleshooting Tips

Identifying Load Issues

- Ensure weight distribution is even across the rack.

- Verify that the load capacity of the racks matches the manufacturer’s specifications.

Checking for Structural Integrity

- Regularly inspect for signs of wear and tear.

- Use a level to ensure the rack is not leaning or misaligned.

Addressing Environmental Factors

- Keep the storage area dry and clean.

- Apply protective coatings to metal parts if necessary to prevent rust and corrosion.

Step-by-Step DIY Repair Guide

Tools You’ll Need

- Wrench

- Screwdriver

- Level

- Hydraulic jack

- Wire brush

- Rust-inhibitor or primer

- Rust-resistant paint

Repairing Bent Arms or Columns

- Empty the Rack: Remove any load from the affected area.

- Use a Hydraulic Jack: For minor bending, use a hydraulic jack to straighten the bent arms.

- Replace Severely Bent Parts: For severe bending, remove and replace the damaged parts with new ones.

Tightening Loose Bolts and Connections

- Identify Loose Bolts: Check all bolts and connections that need tightening.

- Tighten Bolts: Use the appropriate wrench to tighten bolts snugly.

- Ensure Stability: Make sure all connections are secure and test the stability of the rack.

Treating Corrosion and Rust

- Clean the Affected Area: Use a wire brush to remove rust from the metal surface.

- Apply Rust-Inhibitor: Apply a rust-inhibitor or primer to the cleaned area.

- Paint Over: Once dry, paint over with rust-resistant paint to prevent future rusting.

Fixing Impact Damage

- Assess the Damage: Determine if parts need replacement.

- Remove Damaged Parts: If necessary, remove the damaged parts.

- Install New Parts: Install new parts and ensure they are properly secured.

When to Call in Professionals For Cantilever Racks Inspection

Severe Structural Damage: If the damage compromises the overall integrity of the rack, professional assessment and repair are necessary.

Load Capacity Issues: When recalculating and verifying load capacity is required, it’s best to consult a professional.

Compliance and Safety Checks: Regular inspections revealing significant issues should be handled by experts to ensure compliance with safety standards.

Specialised Repairs: Repairs requiring special tools or expertise beyond DIY capabilities should be performed by professionals.

Conclusion

Maintaining Your Cantilever Racking System

Regular inspections and maintenance are crucial to extending the life of your cantilever racking system. Keeping a maintenance log can help track repairs and inspections, ensuring that any issues are addressed promptly.

Choosing the Right Professionals

When professional repairs are needed, choose qualified racking suppliers and repair services with experience in cantilever racking systems. Ensure they have the necessary expertise to handle the specific issues your racks may have.

By following this guide, you can maintain your cantilever racks effectively, ensuring they continue to serve as a reliable part of your storage system. Regular maintenance, timely repairs, and knowing when to call in professionals will keep your storage solutions safe and efficient.

Get in touch with us if you need any assistance.